PE HDPE Membrane Liner Membrane Lining Sheet Extrusion Making Machine

Description

Basic Info.

| Model NO. | LSJ-150/120 |

| Board Layers | Single Plate |

| Screw No. | Single-screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| Three Roller Calendar Material | 45# Forging Steel, 40cr or Alloy Steel |

| T-Die Head | Jc-Times Brand |

| Quality Control | Customers Come to Our Factory to Test |

| Application | Housing Waterproof, Architecture Engineering |

| Capacity | 400-800kg/H |

| Raw Material | PE Virgin and Recycle Material |

| Extruder Model | Sj150/33 |

| Sheet Thickness | 0.5-3mm |

| Sheet Width | 1000-8000mm |

| Transport Package | Wooden Pallets and Cases and Films |

| Specification | LMSB120/33 |

| Trademark | Leader Machinery |

| Origin | Qingdao of China |

| HS Code | 8477209000 |

| Production Capacity | 20 Sets/Per Year |

Product Description

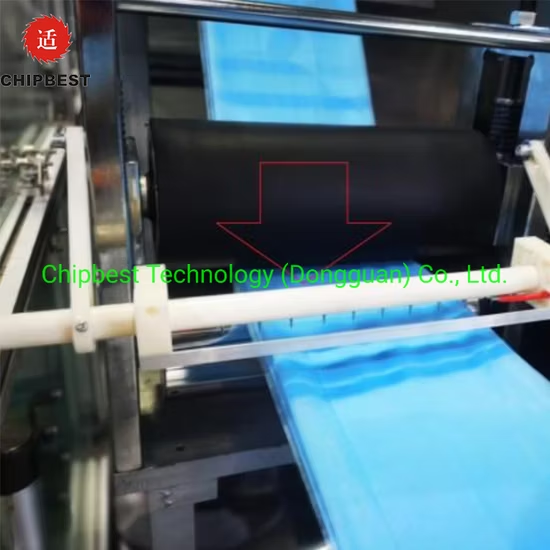

PE HDPE Membrane Liner Membrane Lining Sheet Extrusion Making Machine Product DescriptionThe flat die plus roller calendars extrusion system for geosynthetics geomembrane manufacture is widely known throughout the industry and is generally accepted as the best way to ensure a maximum flatness and consistent thickness and optimum properties of geomembranes. Absorbed and combined both domestic and European advanced technology and experiences, LEADER launched a high capacity extrusion line with low shear & energy consumption. The exclusive design of the main extruder and rollers calendars structure are helpful to smooth the performance of extra-width geomembrane and precision of thickness. The geomembrane is also called also called geomembrane liner geo liners, geomembrane lining material, geo lining products, geomembrane covers,waterproof sheets etc. The geomembrane manufactured by our machine can reach GM 13 standards.

Product Parameters| Model | LMSB120, LMSB150 | LMSB150/150, LMSB160/160 |

| Suitable material | PE | PE |

| Product width | 1000-4000mm | 5000-8000mm |

| Product thickness | 0.5-3mm | 0.8-3mm |

| Max extrusion capacity | 600-700kg/h | 1200-1500kg/h |

1)Gravimetric dosing system for raw material handling

2)High capacity extruders with movable frame

3)Two or three sets of extruders are equipped, can realize the mono layer and also multi-layers co-extrusion

4)Automatic T die and online thickness scanner is optional

5)Exclusive roller calendars and traction structure for maximum flatness & consistent thickness of membranes

6)Both mirror roller calendars and embossing roller calendars are available and replaceable.

7)Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

SHEET SPECIFICATIONS:

Sheet size: width 1000-8000mm, thickness 0.5-0.7-0.8-3mm

Sheet structure: mono layer or multi-layers co-extrusion

Sheets surface: smooth/plain type, textured type, composite geotextile coating type

Processing raw material

PE granules, recycled flakes, carbon black or masterbatch, other filler material etc,

MAIN APPLICATIONS:

1) waterproofing usage in industrial & civil buildings, including the green roof, flat roof, and the sloping roof.

2) Underground waterproof: reservoir, dam, pool, swimming pool,

3) Waterproof usage in tunnel drainage, grain depot, artificial engineering, landfill, artificial lake, foundation moisture-proof

Ma

Company Profilein Features Of The LinPART 5 COMPANY INFORMATION AND MAIN PRODUCTS:

Cooperated Suppliers

PART 6 OUR RELIABLE SUPPLIERS:

Certifications

PART 7 COMPANY CERTIFICATIONS:

PPackaging & Shipping

ART 7 MACHINE PACKING AND DELIVERY

All the machine parts will be packed in wooden cases or pellets with stretching films on machine body.

PART 8 COMPANY OVERSEA SHOWS AND CONTACT DETAILS:

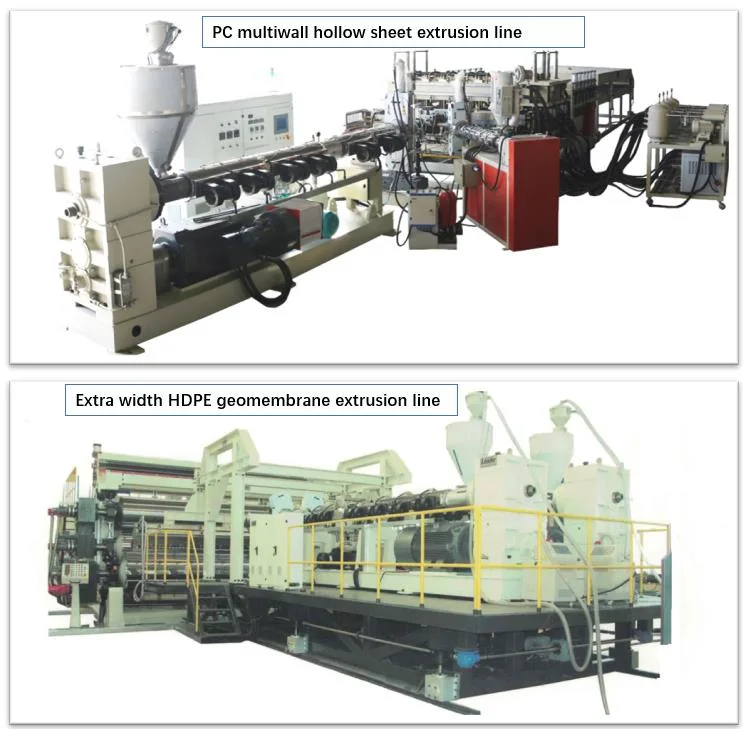

PART 10 OTHER KINDS OF PLASTIC SHEETS/PLATES EXTRUSION LINE RECOMMENDATION :

1. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-650kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

2. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirrmoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

3. ABS/eet extrusion machine:

Processong material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 300-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

4. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity:300-800kg/h

Application: Vacuum forming, bathtube, etc.

5. PE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads., decoration, roofing, etc.

7. PC/PP/PE hollow profile sheet/ sunshine roofing panel machine:

Processing material: PC/PP/PE virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity:200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

8. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

9. PVC free foam/celuka foam board extrusion line

board width: 1220mm, thickness: 1-10mm, 3-25mm

board application: decoration board, advertising boards, exhibition boards

extruder model: SJ-80/156 conical twin screw extruder

max capacity: 350kg/h

certifications: CE, ISO9001-2008

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 700-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

Prev: Good Price Hygiene Machine Automatic Under Pad Making Machine for Bed Sheet Production

Next: Automatic Folding Disposable Non Woven Hospital Bed Sheets Adhesive Surgical Drape Making Machine

Our Contact